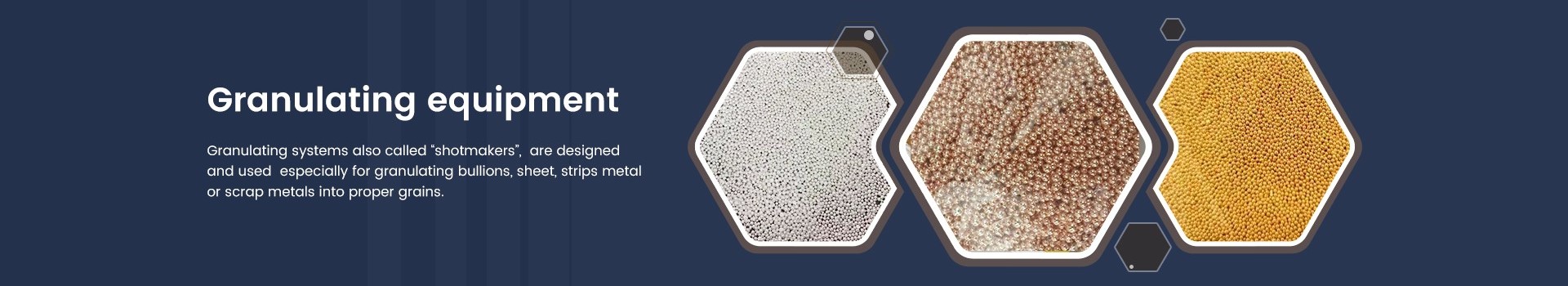

Nidaamyada Granulating

Nidaamyada granulating ee sidoo kale loo yaqaan "shotmakers", ayaa loo qaabeeyey oo loo adeegsadaa si gaar ah granulions bullions, xaashida, xariijimaha birta ama biraha qashinka lagu rido miraha saxda ah. Taangiyada granulating aad bay u fududahay in meesha laga saaro si loo nadiifiyo. Gacan-ka-soo-baxa si fudud looga saaro gelinta haanta. Qalabka ikhtiyaariga ah ee mashiinka shubista cadaadiska vacuum ama mashiinka shubista joogtada ah ee leh haanta granulating ayaa sidoo kale xal u ah granulating marmar. Taangiyada granulating ayaa diyaar u ah dhammaan mishiinnada ku jira taxanaha VPC. Nidaamyada granulating nooca caadiga ah waxay ku qalabaysan yihiin taangiyo leh afar taayir oo si fudud u soo galaya oo u baxaya.

-

Mashiinka Granulator Birta ee Naxaasta Dahabka ah 4kg 6kg 8kg10kg15kg

1. Iyadoo la xakameynayo heerkulka, saxnaanta ilaa ± 1 ° C.

2. Naqshad ultra-bini'aadmi ah, hawlgalku wuu ka fudud yahay kuwa kale.

3. Isticmaal kantaroolaha Mitsubishi ee la soo dejiyay.

4. Granulator Silver oo leh xakameyn kuleyl ah (Mashiinka shubka Dahabka ah ee Dahabka, Mashiinka Granulating Silver).

5. Mashiinkaani wuxuu qaataa tignoolajiyada kuleylka sare ee IGBT, saamaynta wax lagu shubayo waa mid aad u wanaagsan, nidaamku waa mid deggan oo ammaan ah, awoodda dahabka dhalaalaysa waa ikhtiyaari, iyo qeexida birta granulated waa ikhtiyaari.

6. Xawaaraha granulation waa mid degdeg ah oo aan buuq lahayn. Tijaabada horumarsan ee qumman iyo hawlaha ilaalinta ayaa ka dhigaya mashiinka oo dhan mid ammaan ah oo waara.

7. Mashiinku wuxuu leeyahay naqshad kala qaybsan, jidhkuna wuxuu leeyahay meel bannaan oo dheeraad ah.

-

Platinum Granulating System Machine Granulating 10kg

Hasung Platinum Shot Maker Granulating Machine marka la barbar dhigo alaabada la midka ah ee suuqa, waxay leedahay faa'iidooyin aan la qiyaasi karin marka la eego waxqabadka, tayada, muuqaalka, iwm., waxayna ku raaxaysataa sumcad wanaagsan suuqa. iyaga hagaajinaysaa. Tilmaamaha Hasung Platinum Shot Maker Granulating Machine waxa lagu habayn karaa iyadoo loo eegayo baahiyahaaga.

Faa'iidooyinka ugu muhiimsan ee jiilalka cusub ee toogashada

Ku rakibida fudud ee haanta granulating oo leh madal

Waxqabadka granulating tayo sare leh

Ergonomically iyo naqshad dheelli tiran oo si badbaado leh oo sahlan loo maareeyo

Habdhaqanka qulqulka ee la hagaajiyay ee biyaha qaboojinta

Kala saarista la isku halleyn karo ee biyaha iyo granules -

Vakuum Shot Sameeyaha ee Copper Silver Silver 4kg 8kg 10kg

Naqshadeynta nidaamka granulator-ka faakuumka wuxuu ku saleysan yahay baahida dhabta ah ee habka birta qaaliga ah iyadoo la adeegsanayo tikniyoolajiyadda kuleylka casriga ah ee casriga ah.

Granulator-ka vacuum-ka waxaa loo isticmaalaa in lagu soo saaro miro sayid oo tayo sare leh oo isku mid ah oo loogu talagalay biraha qaaliga ah sida dahabka, qalinka, naxaasta, iyo alloysyada, laga bilaabo walxo ceeriin ah oo ay dhalaalisay Hasung induction kuleyliyaha jawiga ilaalinta gaaska ee aan firfircooneyn, ka dibna lagu tuuray haanta biyaha ee gudbaysa. iyada oo loo marayo maro godan oo badan oo u shaqeeya sida qulqulka qulqulka.

granulators vacuum wuxuu si buuxda u qaataa faakuum iyo dhalaalid gaaska aan shaqaynayn iyo granulating, mishiinku wuxuu si toos ah u walaaqi karaa dhalaalidda, walaaqida korantada, iyo qaboojiyaha gudaha qolka dhalaalka + vacuum / gaaska aan firfircoonayn, luminta hoose, dalool la'aan, midab la'aan, iyo muuqaal qurux badan oo leh cabbir isku mid ah.

Qalabkani wuxuu adeegsadaa nidaamka xakamaynta barnaamijka Mitsubishi PLC, SMC pneumatic iyo Panasonic servo motor drive iyo qaybaha kale ee caanka ah ee guriga iyo dibaddaba.

-

Nidaamka Granulating High Vakuum Granulating for Gold Silver Copper 20kg 50kg 100kg

granulator vacuum High granulates Qurub biraha qaaliga ah ee tuurista silig bonding: dahab, qalin iyo naxaas, silig bond waxaa inta badan loo isticmaalaa qalabka semiconductor, alxanka photovoltaic, qalabka caafimaadka, mashiinada sirdoonka macmal ah.Also kuwaas shotmakers biraha vacuum sare waxaa loo horumariyo gaar ahaan bullions granulating. , biraha xaashida ah, ama xoqida miraha saxda ah. Taangiyada granulating waa mid aad u fudud in laga saaro nadiifinta. HS-VGR Mashiinada Fasaxa Granulating High ayaa la heli karaa oo leh awood aan la taaban karin laga bilaabo 20kg ilaa 100kg. Qalabka jirku wuxuu isticmaalayaa 304 bir ah oo aan lahayn taas oo hubinaysa tayada nolosha muddada dheer iyadoo la isticmaalayo naqshad casri ah si loo buuxiyo tayada loo baahan yahay.

Codsiyada waaweyn:

1. Diyaarinta Alloys ka soo baxay dahab iyo aluminium master

2. Diyaarinta qaybaha alloy

3. Diyaarinta alloys ka qaybaha

4. Nadiifinta birta hore loo shubay

5. Samaynta hadhuudh bir ah oo loogu talagalay heshiisyada birta ah ee qaaliga ahTaxanaha VGR waxaa loo sameeyay soo saarista garaafyada birta ah ee leh cabbir hadhuudh ah oo u dhexeeya 1.5 mm iyo 4mm. Nidaamyadu waxay ku saleysan yihiin unugyada granulation Hasung, laakiin dhammaan qaybaha muhiimka ah, gaar ahaan nidaamka jet-ka, waa horumarin gaar ah.

Awoodda weyn sida 100kg vacuum granulating system waa ikhtiyaari in lagu qalabeeyo Mitsubishi PLC Touch Panel nidaamka xakamaynta shakhsi ahaaneed.

Qalabka ikhtiyaariga ah ee cadaadiska faakuumka ama mashiinka tuurista joogtada ah ee leh taangiga granulating waa xal ku habboon granulation marmar. Taangiyada granulating ayaa diyaar u ah dhammaan mishiinnada ku jira taxanaha VC.

Faa'iidooyinka ugu muhiimsan ee jiilalka cusub ee shotmaker:

1. Ku rakibida fudud ee taangiga granulating

2. Isbeddel degdeg ah oo u dhexeeya habka shubista iyo granulating

3. Ergonomically iyo design qumman oo dheellitiran si badbaado leh oo sahlan loo maareeyo

4. Dhaqan socodka la wanaajiyey ee biyaha qaboojinta

5. Kala saarista la isku halleyn karo ee biyaha iyo granules

6. Kuwa ugu awoodda badan uguna waxtarka badan ee kooxaha sifeynaya biraha qaaliga ah.

7. Badbaadinta tamarta, dhalaalid degdeg ah. -

Mashiinka Granulating Birta ee Dahab Silver Silver Alloy 20kg 30kg 50kg 100kg 150kg

1. Iyadoo la xakameynayo heerkulka, saxnaanta ilaa ± 1 ° C.

2. Naqshad ultra-bini'aadmi ah, hawlgalku wuu ka fudud yahay kuwa kale.

3. Isticmaal kantaroolaha Mitsubishi ee la soo dejiyay.

4. Granulator Silver oo leh xakameyn kuleyl ah (Mashiinka shubka Dahabka ah ee Dahabka, Mashiinka Granulating Silver).

5. Mashiinkaani wuxuu qaataa tignoolajiyada kuleylka sare ee IGBT, saamaynta wax lagu shubayo waa mid aad u wanaagsan, nidaamku waa mid deggan oo ammaan ah, awoodda dahabka dhalaalaysa waa ikhtiyaari, iyo qeexida birta granulated waa ikhtiyaari.

6. Xawaaraha granulation waa mid degdeg ah oo aan buuq lahayn. Tijaabada horumarsan ee qumman iyo hawlaha ilaalinta ayaa ka dhigaya mashiinka oo dhan mid ammaan ah oo waara.

7. Mashiinku wuxuu leeyahay naqshad kala qaybsan, jidhkuna wuxuu leeyahay meel bannaan oo dheeraad ah.

-

Cabbirka is haysta Qalabka Granulator Birta ee Qalab Dahab ah

Shoolayaasha birta ee cabbirka yar. Xakamaynta heerkulka, saxnaanta ilaa ±1°C.

Naqshad ultra-biniaadmi ah, hawlgalku wuu ka fudud yahay kuwa kale.

Isticmaal kontaroolaha Mitsubishi ee la soo dejiyay.Mashiinkaani wuxuu qaataa tignoolajiyada kuleylka sare ee IGBT ee Jarmalka, saameynta shubista aad ayey u wanaagsan tahay, nidaamku waa xasiloon oo badbaado leh, awooda dahabka dhalaalaysa waa ikhtiyaari, iyo qeexida birta granulated waa ikhtiyaari. Xawaaraha granulation waa mid degdeg ah oo aan buuq lahayn. Tijaabada horumarsan ee qumman iyo hawlaha ilaalinta ayaa ka dhigaya mashiinka oo dhan mid ammaan ah oo waara. Mashiinku wuxuu leeyahay naqshad kala qaybsan, jidhkuna wuxuu leeyahay meel bannaan oo dheeraad ah.

Isticmaalka kombaresarada hawada la'aanteed, ku shubista adigoo gacanta ku tuuraya istaagida furka farsamada.

Nidaamkan granulating GS Series wuxuu ku habboon yahay awoodda yar ee laga bilaabo 1kg ilaa 8kg awoodda (dahab), waxay u fiican tahay macaamiisha haysta meel yar.

Waa maxay granulation biraha?

Granulation (oo ka yimid Laatiinka: granum = "hadhuudh") waa farsamada dahab-tume ee dusha sare ee dahabka lagu qurxiyey qaybo yaryar oo bir ah oo qaali ah, oo loo yaqaan granules, sida ku cad qaabka naqshadeynta. Natiijooyinka qadiimiga ah ee ugu da'da weyn ee dahabka lagu sameeyay farsamadan ayaa laga helay xabaalaha boqortooyada ee Uur, Mesopotamia waxayna dib ugu noqdeen 2500 BC Laga soo bilaabo aaggan, farsamada ayaa ku fiday Anatolia, Suuriya, ilaa Troy (2100 BC) iyo ugu dambeyntii Etruria (qarnigii 8-aad BC). Waxay ahayd si tartiib tartiib ah u lumay dhaqanka Etruscan intii u dhaxaysay qarnigii saddexaad iyo labaad ee BC taas oo masuul ka ahayd hoos u dhaca granulation. geyntooda dahsoon ee granulation budada ganaaxa2 iyada oo aan si muuqata loo isticmaalin alxanka adag.

Granulation waxay u badan tahay inay tahay tan ugu dahsoon uguna xiisaha badan farsamooyinka qurxinta qadiimiga ah. Waxaa soo bandhigay farsamayaqaannada Fenici iyo Greci ee Etruria qarnigii 8aad ee BC, halkaas oo aqoonta birta iyo isticmaalka biraha qaaliga ah ay mar horeba ku jireen marxalad heer sare ah, khabiirada dahabiga ah ee Etruscan waxay sameeyeen farsamadan iyaga u gaar ah si ay u abuuraan farshaxanno farshaxan oo kakanaanta iyo quruxda aan sinnayn.

Intii lagu guda jiray qeybtii hore ee 1800-meeyadii dhowr qodis ayaa laga sameeyay agagaarka Rome (Cerveteri, Toscanella iyo Vulci) iyo Koonfurta Ruushka (Kertch iyo Taman Peninsula) taas oo shaaca ka qaaday Etruscan qadiimiga ah iyo dahabka Giriigga. Jawharadahaan waxaa lagu qurxiyay granulation. Dahabku wuxuu u yimid dareenka qoyska Castellani ee dahablayaasha kuwaas oo aad ugu lug lahaa cilmi-baarista dahabka qadiimiga ah. Natiijooyinka laga helay goobaha aaska Etruscan ayaa soo jiitay dareenka ugu badan sababtoo ah isticmaalkooda granules aad u fiican. Alessandro Castellani ayaa si tafatiran u darsay agabkan si uu isugu dayo in uu daaha ka rogo habka ay wax u abuuraan. Ma ahayn ilaa horraantii qarnigii 20aad, dhimashadii Castellani ka dib, in halxiraalaha kolloidal/eutectic alxanka ugu dambeyntii la xaliyay.

Inkasta oo sirtu ay qarsoodi u ahayd Castellanis iyo asaagood, dahabka cusub ee Etruscan ee la helay ayaa kiciyay soo noolaynta dahabka qadiimiga ah qiyaastii 1850-kii. Farsamooyinka dahab-samaynta ayaa la ogaaday kuwaas oo u suurtageliyay Castellani iyo kuwa kale inay si daacad ah u soo saaraan qaar ka mid ah dahabkii qadiimiga ahaa ee ugu fiicnaa abid. Qaar badan oo ka mid ah farsamooyinkan ayaa aad uga duwanaa kuwa Etruscans-ka ay shaqaaleeyaan haddana waxay keeneen natiijo la mari karo. Tiro ka mid ah walxaha dahabka ah ee soo noolaynta qadiimiga ah ayaa hadda ku jira ururinta dahabka ee muhiimka ah ee adduunka oo dhan, oo ay la socdaan dhiggooda hore.

GRANULES

Granules waxay ka samaysan yihiin daawaha isku midka ah ee birta ah ee lagu dhejin doono. Mid ka mid ah qaabku wuxuu ku bilaabmaa iyadoo la soo rogo bir aad u dhuuban oo lagu maqayo geeso cidhiidhi ah oo cidhifka ah. Cidhifka waa la gooyay natiijaduna waa labajibbaaran yaryar oo badan ama platelet bir ah. Farsamo kale oo lagu abuurayo hadhuudh waxay isticmaashaa silig dhuuban oo lagu duuduubay meel dhuuban oo dhuuban, sida irbad oo kale. Gariiradda ayaa markaa la gooyaa siddooyin bood ah oo aad u yar. Tani waxay abuurtaa siddo simmetrical ah oo keena granules si siman u siman. Hadafka ayaa ah in la abuuro qaybo badan oo isku mid ah oo leh dhexroor aan ka badnayn 1 mm.

Birta platelets ama giraangiraha boodboodka waxaa lagu dahaadhay budada dhuxusha si looga ilaaliyo inay isku dhegaan marka la tooganayo. Qeybta hoose ee qolofka waxaa lagu daboolay lakabka dhuxusha oo birta ayaa lagu rusheeyaa si ay u siman yihiin inta suurtogalka ah. Tan waxaa ku xiga lakab cusub oo budada dhuxusha ah iyo qaybo bir ah oo badan ilaa ay ka buuxsami karto qiyaastii saddex-meelood saddex meelood. Weelka waxaa lagu shideeyaa foornada ama foornada, iyo qaybaha birta ah ee qaaliga ah waxay isu rogaan meelo yaryar oo heerkul ah oo dhalaalaysa. Qaybahan cusub ee la sameeyay ayaa loo daayay inay qaboojiyaan. Ka dib waxaa lagu nadiifiyaa biyaha ama, haddii farsamada alxanka la isticmaalo, lagu qaado aashitada.

Granules ee cabbirka aan sinnayn ma dhalin doono naqshad lagu farxo. Mar haddii aanay suurtogal ahayn in dahab-tustuhu uu abuuro goobo is-daba-joog ah oo isla dhexroor ah, waa in la kala soocaa ka hor inta aan la isticmaalin. shaandho taxane ah ayaa loo isticmaalaa in lagu kala saaro granules.

Sideed u samaysaa darbo dahab ah?

Habka samaynta toogashada dahabka miyay tahay in dahab la dhalaaliyay si tartiib ah loogu shubo biyaha kadib markaad kululayso? Mise hal mar baad wada samaysaa? Waa maxay ujeedada samaynta toogashada dahabka halkii laga samayn lahaa ingots ect.

Darbada dahabka ah laguma abuurin in laga soo shubo faruuryaha weelka. Waa in lagu sii daayaa sanbabada. Waxaad samayn kartaa mid fudud adiga oo dalool yar (1/8) ka qodaya xagga hoose ee saxanka dhalaalaysa, kaas oo lagu dul shubi doono weelka biyaha, oo toosh uu ku dul ciyaarayo saxanka, godka agtiisa. dahabka ka barafoobay saxanka marka laga soo wareejiyo saxanka dhalaalaysa ee budada dahabka ah lagu dhalaaliyo Sababaha had iyo jeer igu adkeyd inaan fahmo, in ay sameeyaan xabbado, halkii galley.

Xabada waxaa doorbida kuwa isticmaala dahabka, waayo waxay ka dhigaysaa mid fudud in la miisaamo inta la rabo. Dahab-tuurayaasha caqliga leh hal mar kuma dhalaalin dahab badan, haddii kale waxay keeni kartaa in la shubo cillado (gaas ku darida).

Marka la dhalaaliyo oo kaliya inta loo baahan yahay, qadarka yar ee ka soo hadhay (sprue) ayaa lagu dhalaali karaa dufcada soo socota, iyada oo la hubinayo in dahab dib loo dhalaalay uusan ururin.

Dhibaatada dhalaalaysa dahabka mar iyo mar kale ayaa ah in birta saldhiga ah (sida caadiga ah naxaasta, laakiin aan ku xaddidnayn naxaasta) ay oxidizes oo ay bilaabaan abuurista gaas ku urura jeebab yaryar oo shub ah. Badi dahab-yaqaan kasta oo wax shuba waxa uu lahaa khibradaas, waxana uu inta badan xisaabiyaa sababta ay u diidayaan, ama ma door bidaan in ay isticmaalaan dahab hore loo isticmaalay.